Wood And Tile Printing

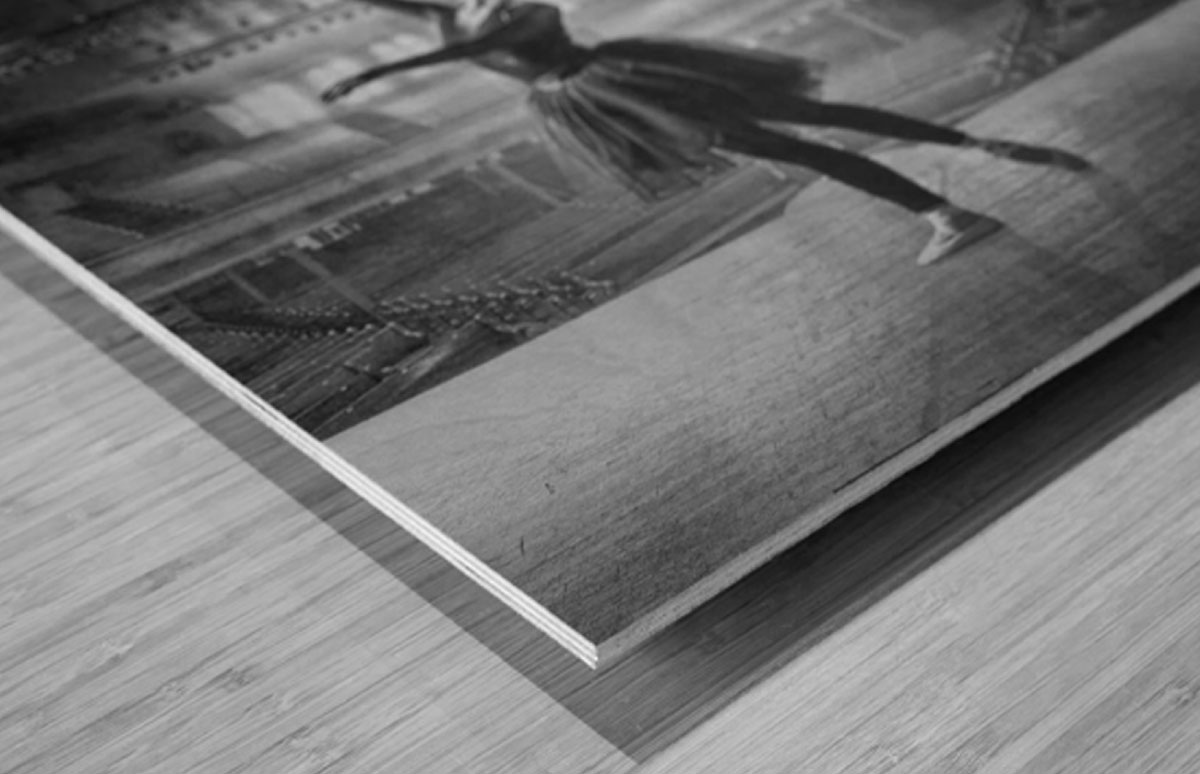

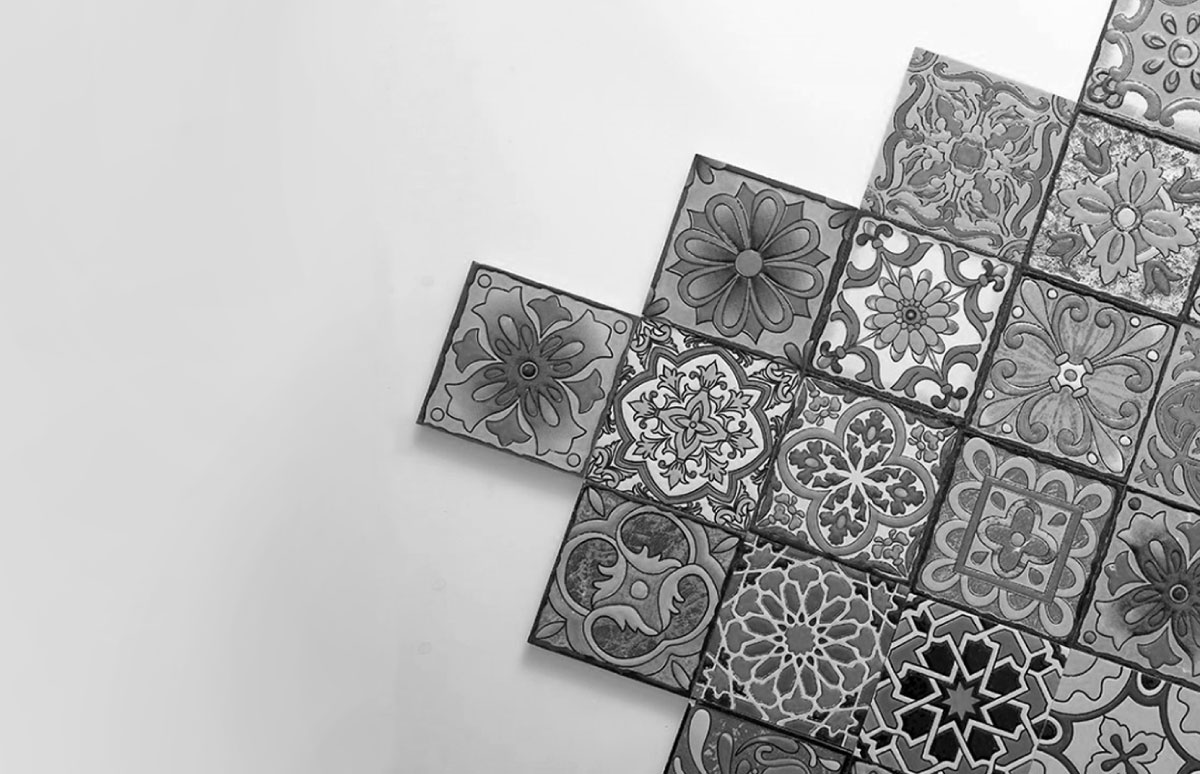

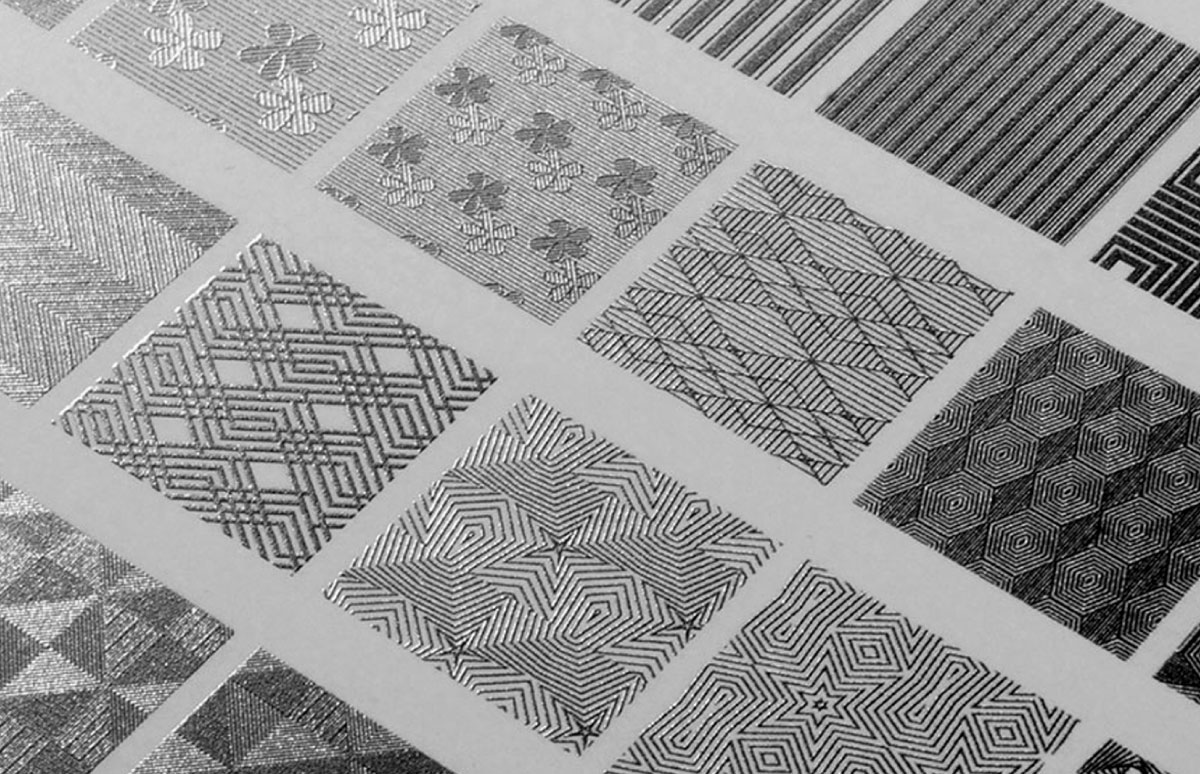

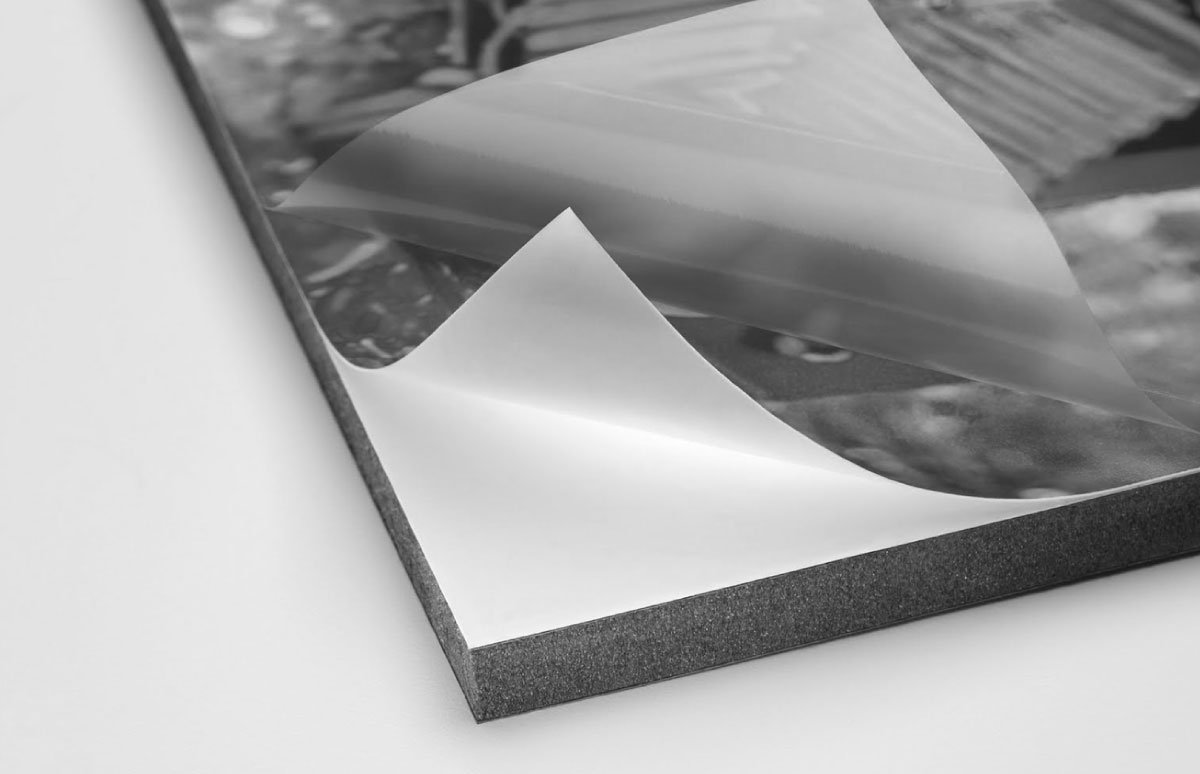

Wood and tile printing are popular methods of printing that use ultraviolet (UV) light to create high-quality images on wooden and tile surfaces. This printing technique is commonly used in industries such as architecture, interior design, and product branding, where the durability and aesthetic appeal of wood and tiles are essential. The process of wood and tile printing involves the preparation of the surface. The surface is thoroughly cleaned and treated with a special coating that allows the UV ink to adhere to it. Once the surface is prepared, the image to be printed is transferred to the surface using a high-resolution printer that uses UV inks. The UV inks used in wood and tile printing are specially designed to dry quickly when exposed to UV light. This ensures that the printing process is fast and efficient, allowing for large volumes of prints to be produced in a short amount of time. Additionally, UV inks are extremely durable, ensuring that the printed images on the surface remain vibrant and fade-resistant even under harsh environmental conditions. Wood and tile printing offers a number of benefits over other printing methods. For one, it can be used on a wide range of wooden and tile surfaces, including floors, walls, and furniture. Additionally, the images produced by wood and tile printing are of the highest quality, with sharp details, bright colors, and a glossy finish that replicates the natural grains and textures of the surface. Another benefit of wood and tile printing is that it allows for customization and personalization of these surfaces. For example, wooden furniture can be printed with custom designs or logos, while tile floors can be printed with patterns and textures that match the overall interior design of a space. In conclusion, wood and tile printing are two popular printing techniques that use UV light to produce high-quality images on wooden and tile surfaces. These methods offer numerous benefits, including durability, vibrancy, and fast printing speeds, and can be used to create customized and personalized surfaces for a range of applications.