Xanita Board

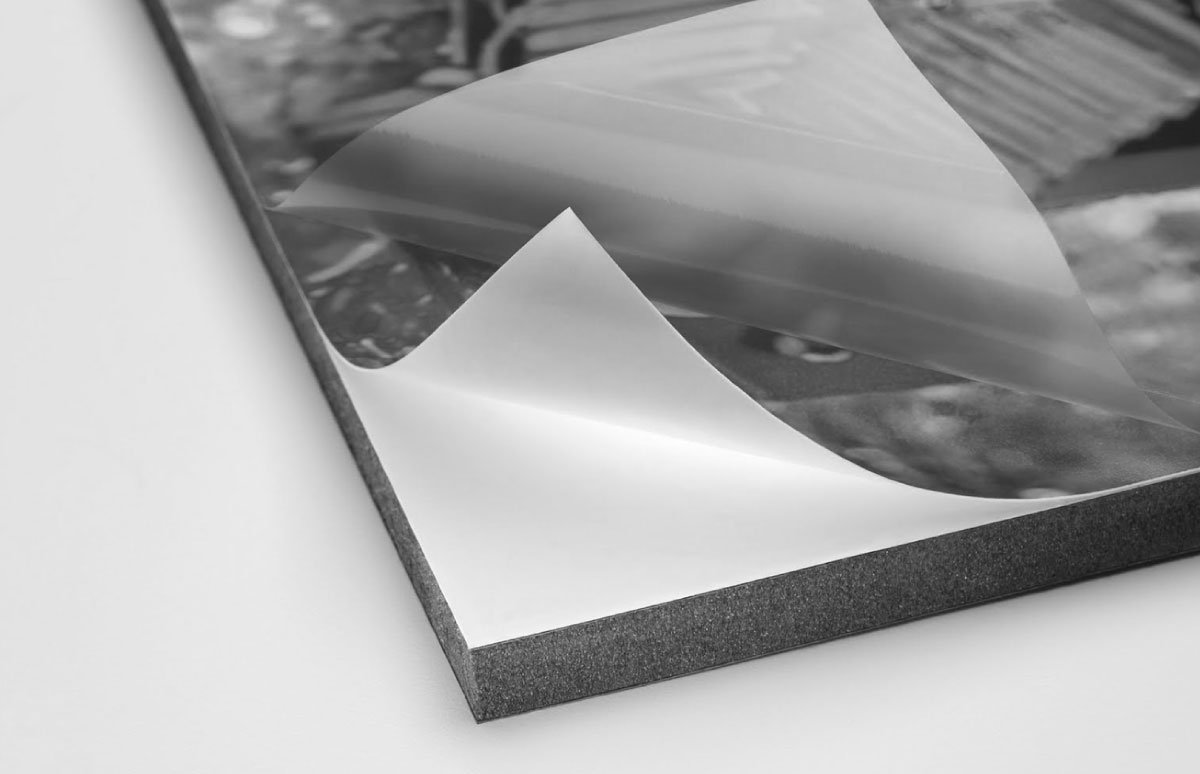

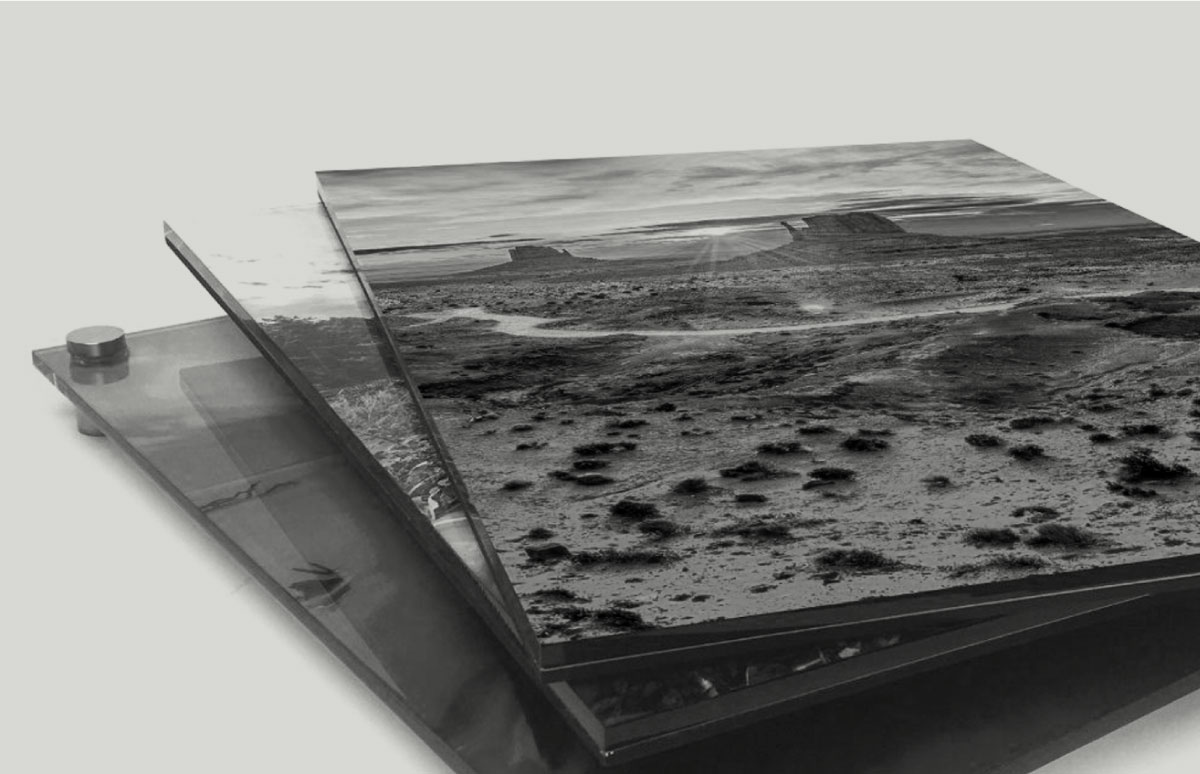

Xanita board is a versatile, lightweight, and sustainable alternative to traditional wood-based materials, made from 100% post-consumer kraft paper waste. It is widely used in the display, exhibition, and packaging industries. Xanita board printing is a popular method of printing that uses ultraviolet (UV) light to create high-quality and vibrant images on Xanita board surfaces. The process of Xanita board printing involves the preparation of the surface. The Xanita board is thoroughly cleaned and treated with a special coating that allows the UV ink to adhere to it. Once the surface is prepared, the image to be printed is transferred to the Xanita board using a high-resolution printer that uses UV inks. The UV inks used in Xanita board printing are specially designed to dry quickly when exposed to UV light. This ensures that the printing process is fast and efficient, allowing for large volumes of prints to be produced in a short amount of time. Additionally, UV inks are extremely durable, ensuring that the printed images on the Xanita board surface remain vibrant and fade-resistant even under harsh environmental conditions. Xanita board printing offers a number of benefits over other printing methods. For one, it is a sustainable material, made from 100% post-consumer kraft paper waste, making it an environmentally friendly choice. Additionally, it is a lightweight material that is easy to handle and transport, making it ideal for use in exhibitions and displays. The images produced by Xanita board printing are of the highest quality, with sharp details, bright colors, and a matte or glossy finish. Xanita board is also easy to cut and shape, making it ideal for creating custom display structures and packaging designs.